Windows & Doors

Windows World

Windows, which illuminate the architecture, are eyes to the soul of the structure, whether it’s a public space or a private residence. Today, technological advances in glass and sash materials have created new options for the design of traditional-style windows that enhance history without sacrificing aesthetics.

Here are some of the designers and fabricators who are leading the way back to revisiting the past.

Allied Window Inc.

Established six decades ago, family-owned Allied Window, which is based in Ohio, manufactures custom interior and exterior “invisible” storm windows for residential, industrial, and commercial buildings.

“Our capabilities in the historic or ‘special’ project area are unmatched in the industry,” says president Dave Martin. “We can provide narrow-line windows of any shape, size, or color that seem to ‘disappear’ into the window opening. Further, our custom-designed windows can, when necessary, conform to national historic standards.”

By using aluminum extrusions in its manufacturing process, Allied creates windows that are strong yet capable of being bent into special shapes, even in larger units.

The company’s windows have been installed in a number of U.S. presidents’ homes, including Monticello, Montpelier, and The Hermitage, governor’s mansions, state capitols, and historic buildings, including Boston’s Faneuil Hall.

“We are the go-to for the ultimate in custom storm windows—whether it be large openings, custom shapes, bowed, custom colors, special glazing, or difficult designs due to challenging out-of-square openings,” Martin says. “Our forte is the capability to address challenging field conditions. Recently, an architect commented, ‘Allied Invisible Storm Windows are so invisible, even architects can’t see them!’”

Cooper Historical Windows and Liberty Restoration Glass

Specializing in restoring and reproducing historical wood, steel, and aluminum windows, Cooper Historical Windows and Liberty Restoration Glass (The Cooper Group) preserves the original window frame, sash, and trim whenever possible, reproducing new components only where required to match details of the original.

“We put equal value on historical accuracy and energy efficiency, and often we see one being sacrificed,” says Brian Cooper, president and CEO of the Connecticut-based company. “Every historic preservation project is different, and our goal is to be utilized as a resource, to offer solutions, and to assist in choosing the correct window application.”

The Cooper process starts with the glass—the company offers simulated divided lites, leaded glass in diamond pane or traditional leaded rectangular glass, historical laminated safety glass, historical tempered glass, historical molded glass, and historical hurricane-shield glass.

The glazing, Cooper says, is the engine that drives the window. “We have developed a restoration glass that

enables us to build both single-pane

glass and insulated glass units to the very

highest standards, matching most cylinder glass from 1800 to 1920,” Cooper says. “Today, our Liberty Restoration Glass insulated glass units look historically accurate and deliver the best energy performance values in the industry, capable of surpassing R values over 11.”

The company uses Accoya, a renewable plantation pine, when replicating sash. “Once it is acetalized, the wood does not absorb moisture, so there’s no swelling or shrinking of the window, so there’s no dry rot,” Cooper says. “This also means the paint job will last longer. Accoya will last outdoors for 50 years with no finish on it. And we use water-based finishes on our windows.”

Cooper’s historical windows can be used to customize the energy efficiency of each side of a structure. “We can design the south/west side of a building with our restoration glass insulated glass units and add SC-75 coated film to control the solar heat gain and deal with warming climate and lower air-conditioning costs substantially,” Cooper says. “For the north/east sides, we can build a restoration glass insulation glass unit using TC-88 to maximize the reflection of heat back into the building, thus lowering energy costs. This has never been available in a historical window before.”

Graham Architectural Products

In business for over 40 years, Graham Architectural Products manufactures fully tested and certified Architectural Window-rated retrofits and new-construction windows for historic, high-end multi-family and commercial buildings.

The windows, which are aluminum extrusions with various types of thermal breaks, give the company the ability to create nearly any shape, allowing it to replicate various shapes and materials, such as wood and steel.

The windows are designed in house, or, in the case of historic projects, site visits, review of original drawings and photographs, and demands of historic tax-credit approvals and local codes are the drivers.

The company, which is based in Pennsylvania, has provided windows for numerous historic projects, including New York City’s Starrett-Lehigh Building and the Moynihan Train Hall.

“Our attention to detail in matching historic profiles and sightlines and ensuring that the delivered product meets expectations are what set us apart,” says Bill Wilder, director of technical sales. “Our design team does a great job of looking at ornate copings, mullions, and trim details and not only replicating the basic shape, but also ensuring the joinery fits and leaves a clean, concise appearance, which can be a challenge with aluminum when dealing with

complex shapes.”

Mon-Ray Inc.

Since 1947, Minnesota-based Mon-Ray has been manufacturing secondary-glazing windows and doors for residential and commercial projects around the country, with a keen focus on energy savings, sound abatement, and historic preservation.

Mon-Ray windows have been installed in a number of highly recognizable public buildings, including Winterthur, the Old South Church in Boston, Harvard University, and New York City’s Woolworth Building.

The products are made mainly of aluminum, which offers a number of advantages, including the ability to provide high performance with smaller profiles and sightlines than wood or vinyl, a factor that’s especially important in the historic preservation market.

“Our storm windows are designed to minimize any visual impact,” says national sales manager Jim Nelson. “They ‘disappear’ into the opening, maintaining the original appearance of a historic structure. We offer an exterior aluminum storm window that was specifically designed to match the sightlines and profiles of traditional wood millwork windows and storms. Our goal is to provide performance that meets, and often exceeds, the performance of replacement windows when working in tandem with the original historic window without impacting the original appearance of the window openings.”

Parrett Windows & Doors

Established in 1982, Parrett Windows & Doors specializes in the manufacture of wood and aluminum-clad windows of all styles, shapes, and configurations for private residences, religious institutions, historic buildings, and commercial enterprises.

“We build to specification in a durable, premium-quality design,” says president Ron Safford. “We are capable of handling any size project, from a single window to hundreds of units.”

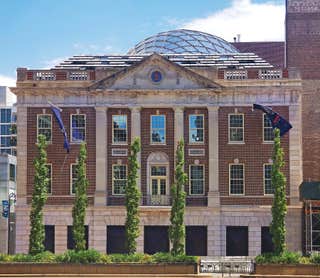

The family-owned and -operated company, which is based in Wisconsin, reproduces historic replicas from architectural or customer specifications. Its windows and doors are installed in a variety of high-profile projects in the United States, including New York City’s Tammany Hall Building, which dates to 1928-29.

Parrett, whose factory has solar panels on its roof, is a green company. The glass used in its windows and doors qualifies for Energy Star status; its wood, much of it from managed forests, is Forest Stewardship Council–certified; components are sourced from a 500-mile radius of its factory headquarters, and many of its production materials are recycled or reused.

“What makes us different from our competitors is our capability, the quality and durability of our products and our many years of experience and accumulated knowledge,” Safford says.

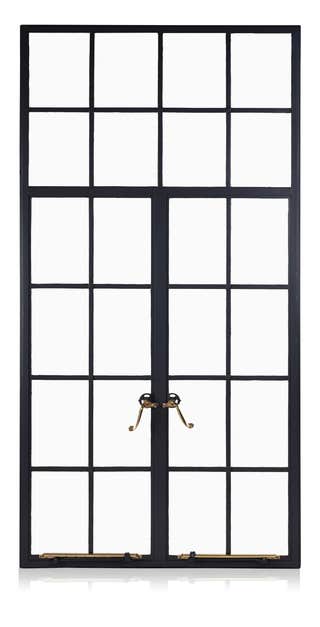

Seekircher Steel Window

A specialist in the repair and refurbishment of historic rolled-steel casement windows and doors, primarily from the 1920s and 1930s, Seekircher Steel Window also has a collection of several thousand vintage examples that it restores and sells.

The family-owned and -operated company, which has been in business for over four decades, has restored windows for buildings throughout the United States, including Frank Lloyd Wright’s iconic Fallingwater, and The Cathedral Church of Saint John the Divine in New York City.

Seekircher Steel Window also builds custom pieces, following traditional casement window styles, sometimes outfitting them with vintage brass or bronze hardware.

“Often, we will use vintage doors and build custom side lights to fill a larger opening,” says Todd Seekircher, owner and president of the company, which was founded by his father. “Or if we’re doing a project involving vintage steel windows—restoring someone’s windows or selling them restored pieces from our collection—we can build doors to match.”

Vintage windows, he says, speak not only of aesthetics but also of sustainability, a highly prized quality in today’s renovation and restoriation market.

“The embodied energy in these windows that often are 90 to 100 years old and the fact that they can and will last for decades, if not centuries more, really speaks to the quality of materials and craftsmanship when they were originally made,” he says.

Seekircher notes that steel windows are enjoying a renaissance, with homeowners, designers, and architects using them as interior partitions or to bring natural light and elegance into a variety of spaces, including offices, wine rooms, and kitchens.

“I love the creative process and collaborating with homeowners, architects, preservationists, and interior designers who are enthusiastic about our product. Being able to see the transformation and execution of a job is a real thrill,” he says, adding that he’s directly involved with every project the company does. “There’s nothing like seeing rusty old windows and paint-marred brass hardware transformed into a show-stopping feature in someone’s home—we take great care with every project.”

Additional Key Suppliers

- Arch Angle Window and Door www.archangleohio.com

- Artistic Windows & Doors www.artisticdoorsandwindows.com

- HeartWood Fine Windows & Doors www.heartwoodwindowsanddoors.com

- Hope’s Windows www.hopeswindows.com

- Innerglass Window Systems www.stormwindows.com

- J.A. Gulick Window Co. www.jagulick.com

- Jim Illingworth Millwork www.jimillingworthmillwork.com

- Kolbe Windows & Doors www.kolbewindows.com

- Marvin www.marvin.com

- St. Cloud Window www.stcloudwindow.com

- Trimline Custom Windows www.trimlinewindows.com

- Zepsa Industries www.zepsa.com